Industrial and Commercial Cranes

Centex Material Handling designs, manufactures, installs and services complete industrial and commercial cranes for businesses and manufacturers in Texas. We also have a wide variety of solutions including hoists, trolleys, accessories and replacement parts for most major brands. Below please find a list of our overhead material handling systems solutions with more information available on our most popular options, as well as a list of all additional services we provide.

- 24 hour availability

- Emergency repairs for most brands of hoists and cranes

- Parts for all Crane and hoist brands

- Scheduled preventative maintenance service programs

- Certified proof load testing of cranes and hoists

- OSHA Certification Inspections and OSHA compliance testing

- Modernization, modification, and upgrades to existing crane systems

- Below the hook slings, spreader bars, lifting attachments

- Ergonomic, light capacity handling systems for assembly, warehouse and distribution handling

- Turnkey crane systems

We design, manufacture and install complete overhead material handling system solutions such as bridge cranes, hoists, chain hoists, wire rope hoists, air hoists, pendant controls and radio controls. Below are our most popular options, but here is the full list of solutions we offer:

- Top Running Single Girder

- Under Running Single Girder

- Top Running Double Girder

- Under Running Double Girder

- Gantry Crane

- Single Leg Gantry Crane

- Floor Mount Jib Crane

- Wall Mount Jib Cranes

- Free Standing Work Stations

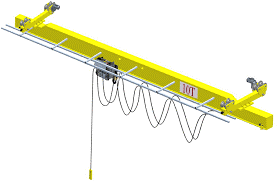

Single Girder Bridge Crane

This type of overhead crane is configured with a single bridge girder, two end trucks, and a trolley hoist which runs along the bottom flange of the bridge girder between the end trucks. A single girder crane is easy to install and is generally used in applications that require light to medium lifting or in buildings where headroom is limited.

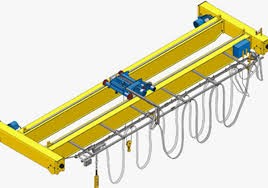

Double Girder Bridge Crane

A double girder overhead crane configuration is made up of two bridge girders, two end trucks, and a trolley hoist. The trolley hoist travels on top of rails that are mounted on top of the bridge girders, giving it greater maximum span and capacity. These cranes are ideal for heavy loads and frequent operation.

Under Running Bridge Crane

Under-running or under-hung cranes are designed for flexibility and functionality. The bridge of an under-running or under-hung crane is engineered to travel along the bottom flange of a runway beam. These cranes can be suspended directly from an overhead building structure without the need for interfering support columns. This ergonomic design offers high usability and versatility.

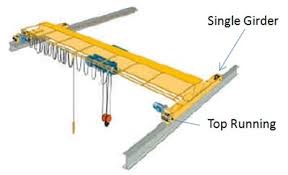

Top Running Bridge Crane

Top-running cranes are designed to lift massive loads, under-hung cranes provide an ergonomic design that offers versatility and usability. The bridge of a top running crane is designed to travel on rails that are mounted onto the runway beams. The beams can be supported by either precisely engineered free-standing columns or by the existing columns of the building.

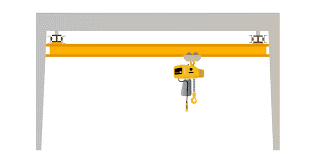

Gantry Crane

A gantry crane can be designed with either a single or double girder bridge. However the main difference is that the gantry girders are attached to legs on both sides of the span. The end trucks are at the bottom of the legs allowing it to travel directly on the ground or on a rail system. This can be either laid on top of the floor or embedded in the floor enabling it to be completely mobile by eliminating a column or overhead runway system. Gantry cranes are a great alternative to large, permanent systems because gantry cranes offer up to 15-tons of lifting capacity.

Jib crane

A jib crane is another great solution for many specific needs of a business. The jib design is made up of a boom (cantilever) mounted to a column. With this simple design, the trolley hoist assembly can move back and forth across the boom and can be engineered to rotate a full 360 degrees. It is a cost-effective and portable crane solution that is easy to operate and doesn’t require specific training.

Freestanding Workstation Crane

Freestanding workstation cranes are a floor supported system that does not put stress on the building’s overhead structure. The installation is straightforward and easier on future relocation. They provide a highly effective, cost efficient lifting and moving solution. Freestanding workstation cranes extend lifting coverage and provide full access of movement. They can replace multiple cranes with one fluid system for improved efficiency and productivity. Free Standing systems require a reinforced concrete floor of at least 6 inches.

- Capacities from 150 to 4000 pounds

- Rectangular Coverage with up to 34 foot bridge and 124 foot runway standard

- Standard support distances of 20, 25, and 30 feet.

- Easy to move and position loads

- Modular design for greater flexibility

- Doesn’t require existing support structure

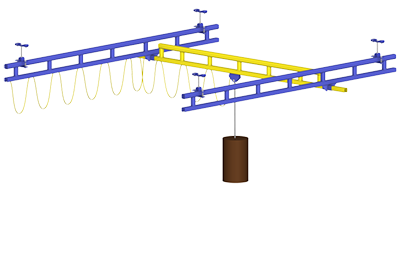

Ceiling Mounted Workstation Crane

Ceiling Mounted Systems make the most of your existing building and production floor space by hanging from existing building beams or trusses. They require no system support columns, no attachments to building columns, and they take up no production floor space. Ceiling mounted workstation cranes are a cost effective and ergonomic material handling solution ideal for many warehousing and manufacturing businesses.

- Capacities from 150 to 4000 lbs.

- Rectangular coverage with up to 34 foot bridge and 124 foot runway standard

- Standard support distances of 20, 25, and 30 feet.